قصتنا

كيف وصلنا إلى هنا؟

في شتاء عام 2013…

كان الجو باردًا جدًا، والثلج يغطي الأرض، وكنت أستمتع بـ"موعدي الأول" مع صديق في مطعم فندق مالميزون، ليدز، إنجلترا.

حدثت أربعة أشياء لا تُنسى في ذلك المساء...

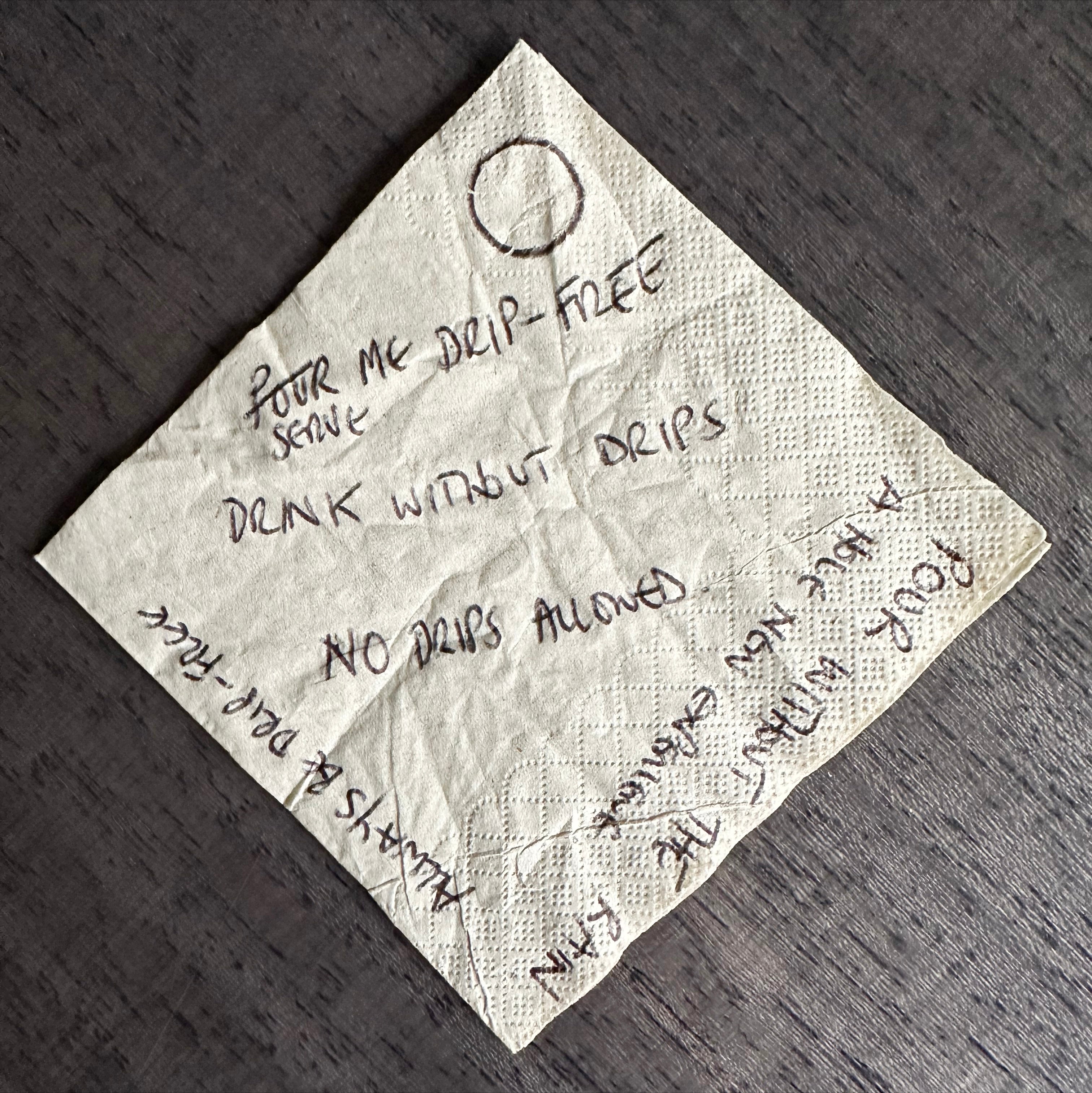

· بينما كان النادل يسكب الشمبانيا، سكب الماء على فستاني.

· علّق أحدنا بشيء مثل "يجب أن يجففوا الزجاجة بعد رفعها من دلو الثلج".

· علمنا أن جراد البحر، طبقه المفضل على الإطلاق، يُسبب الآن لنيك مرضًا شديدًا.

· التقيت بزوجي المستقبلي.

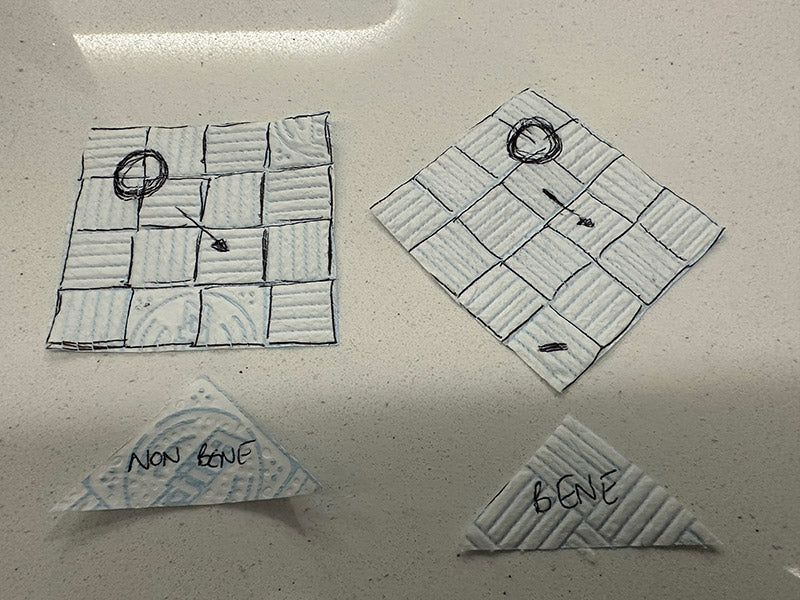

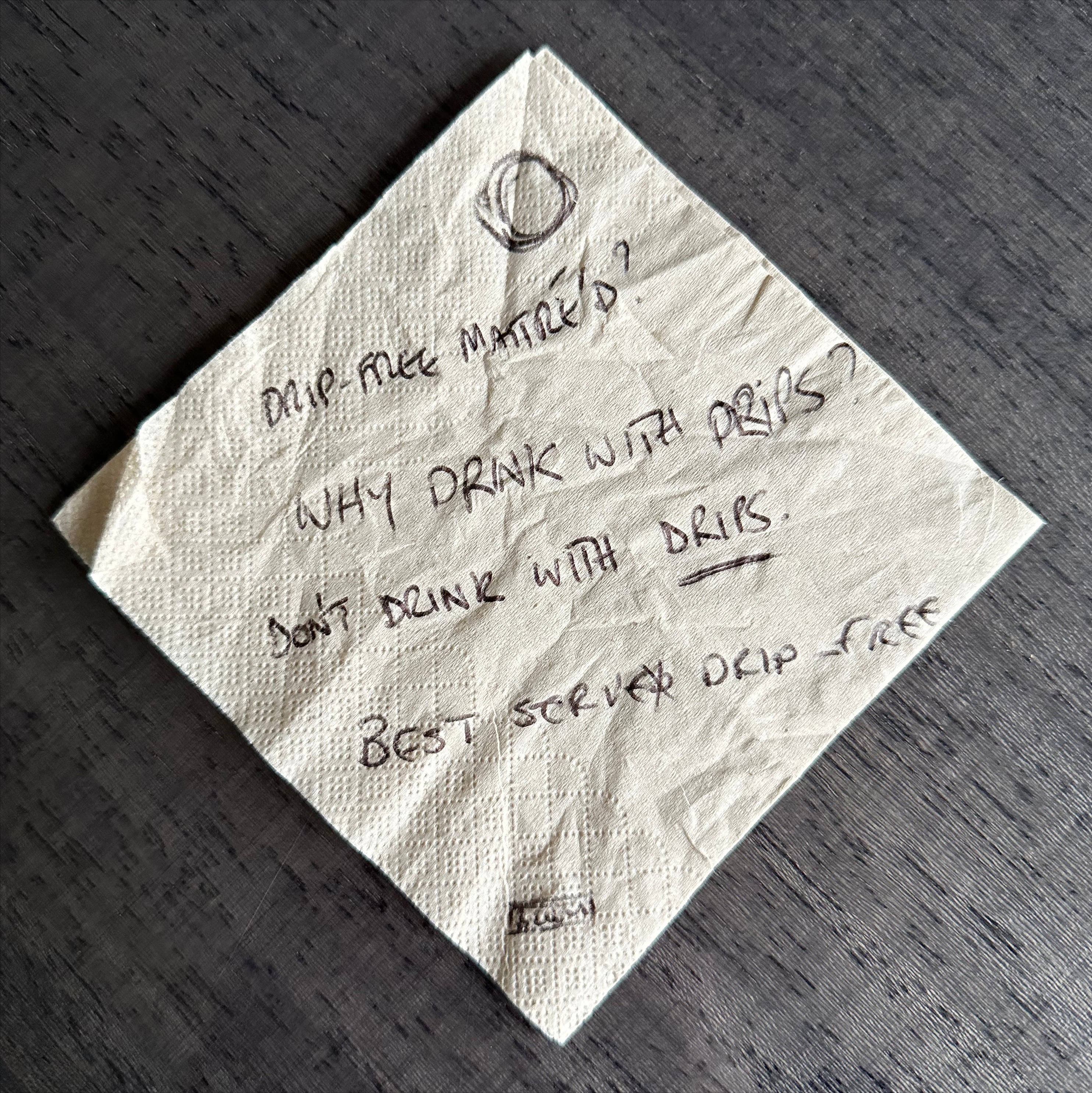

ما زلنا نتجادل حول من صاحب فكرة الطبق، ولكن بحلول الوقت الذي وصلت فيه لوحة الجبن، كان رجل الأعمال الذي أمامي قد رسم أول "قماش زجاجة" في العالم وكان يضحك على "الفرصة التجارية المذهلة التي أتاحتها".

بعد عقد من الزمان، كنا نحتفل بعيد ميلاد في المنزل. قدّم نيك نبيذي من دلو ثلج، وكما توقعت... الماء في كل مكان على الطاولة. مرة أخرى. كان ذلك كافيًا لإثارة جنون أي عاشق للنبيذ! هكذا كان الأمر. كنت أعرف بالفعل كيفية حل هذه المشكلة، وكنت على وشك إطلاق مشروعي التجاري الأول.

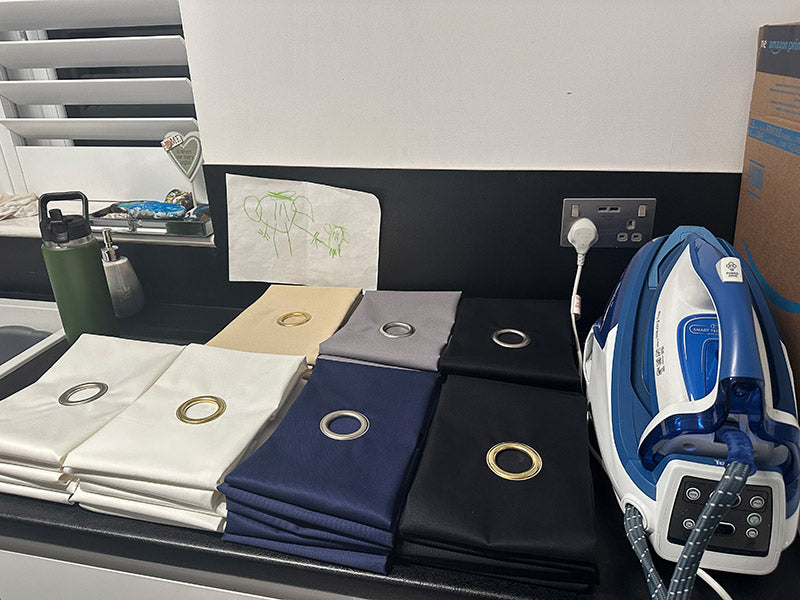

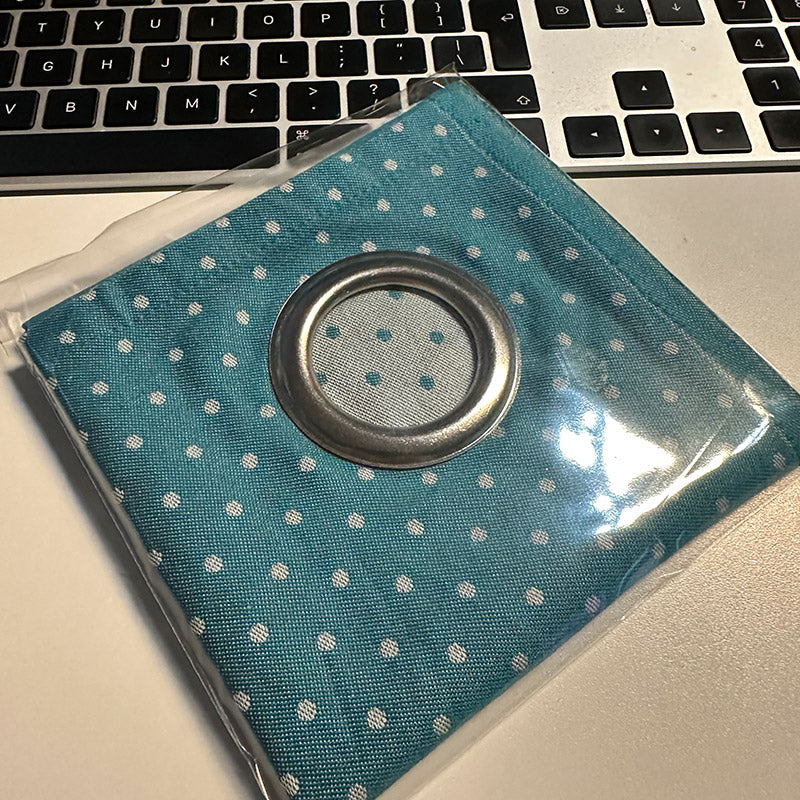

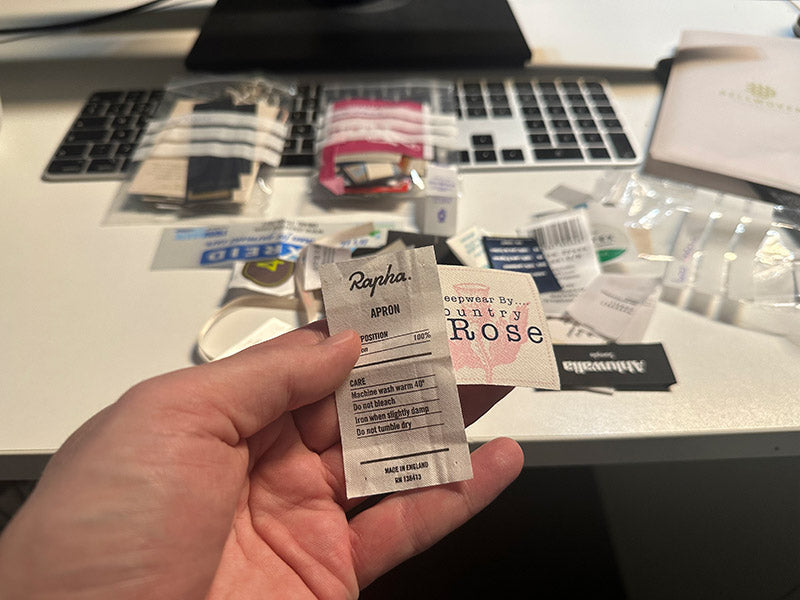

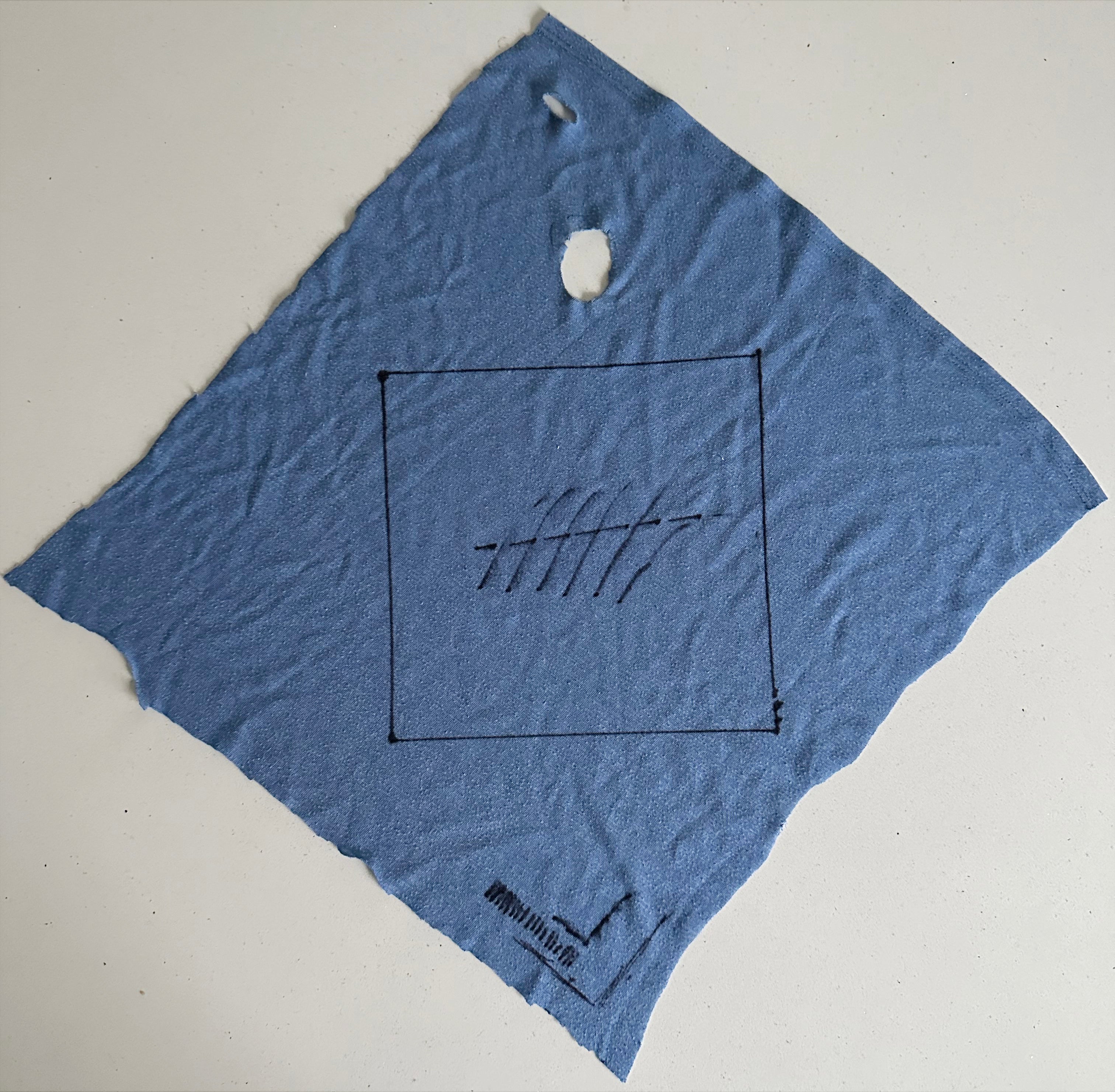

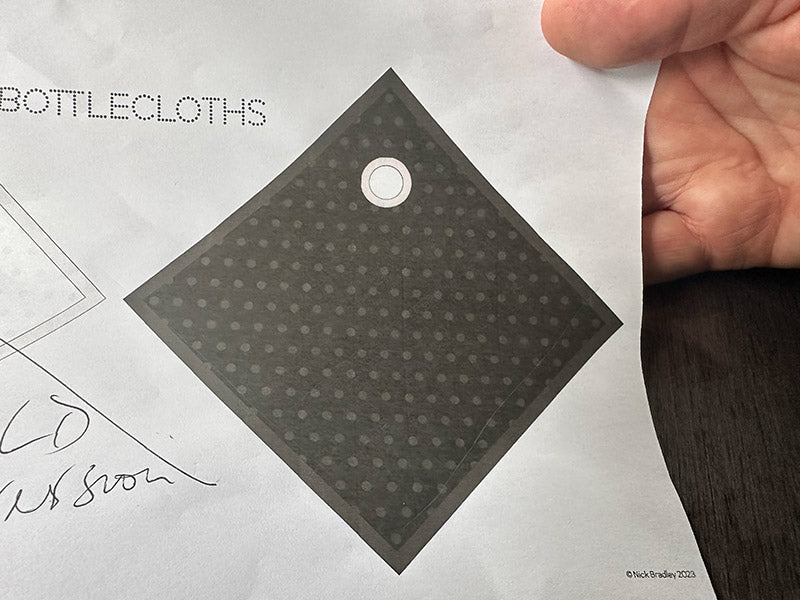

خلال عام ٢٠٢٣، أمضينا ستة أشهر في البحث والتصميم والتخطيط وحماية فكرتنا.

أنشأنا مكتبًا وورشة عمل وموقعًا إلكترونيًا. سافرنا حول العالم لنتعلم عن الأقمشة والأنوال والخياطة والمعادن والغسيل والمواد الكيميائية وغيرها. تحدثنا إلى خبراء النبيذ وأصحاب الفنادق والمطاعم ومُلّاك العقارات. زرنا موردين ومهندسين ومصانع وتجار تجزئة، وبالطبع مصانع نبيذ مختلفة خلال رحلتنا.

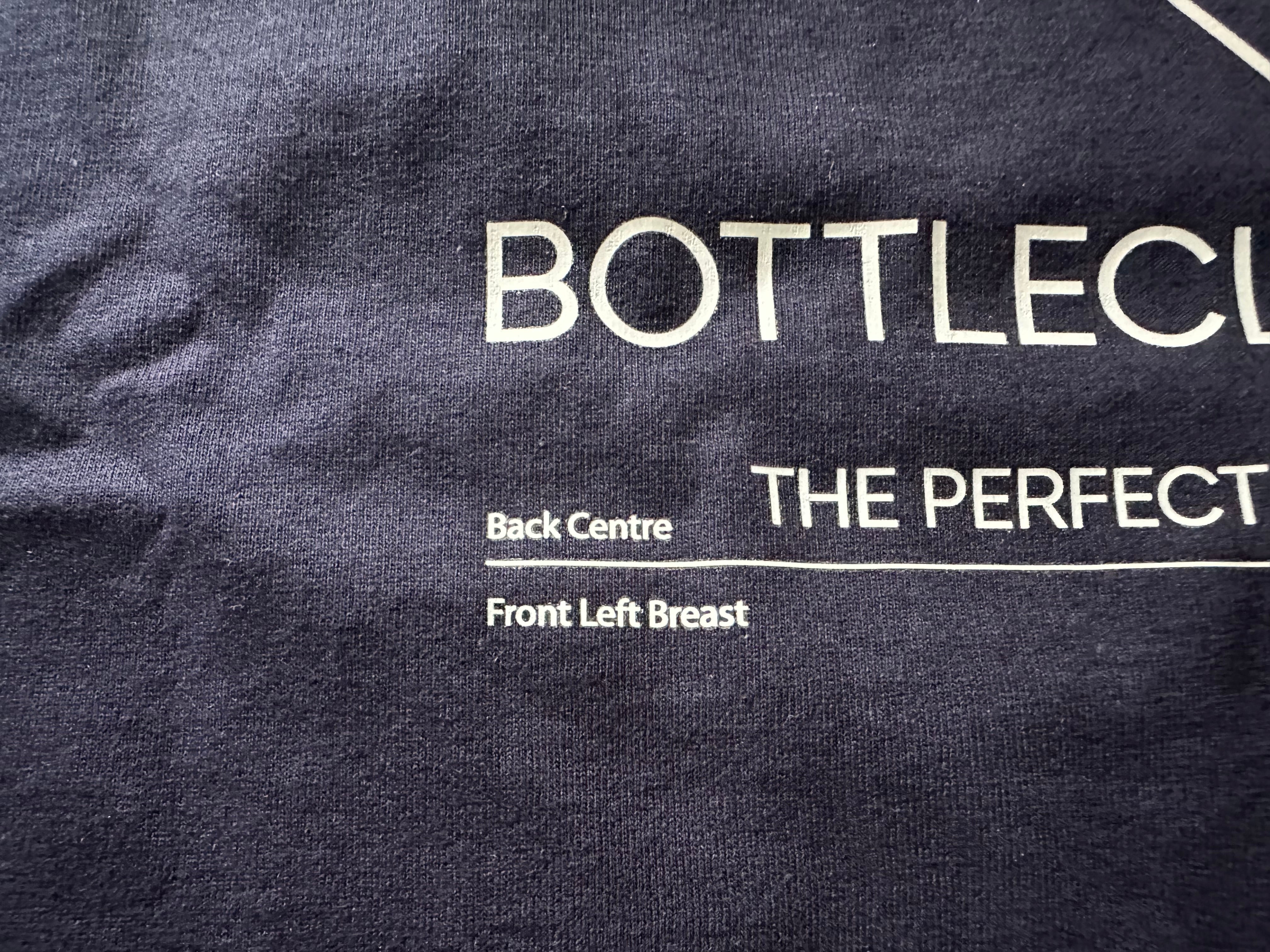

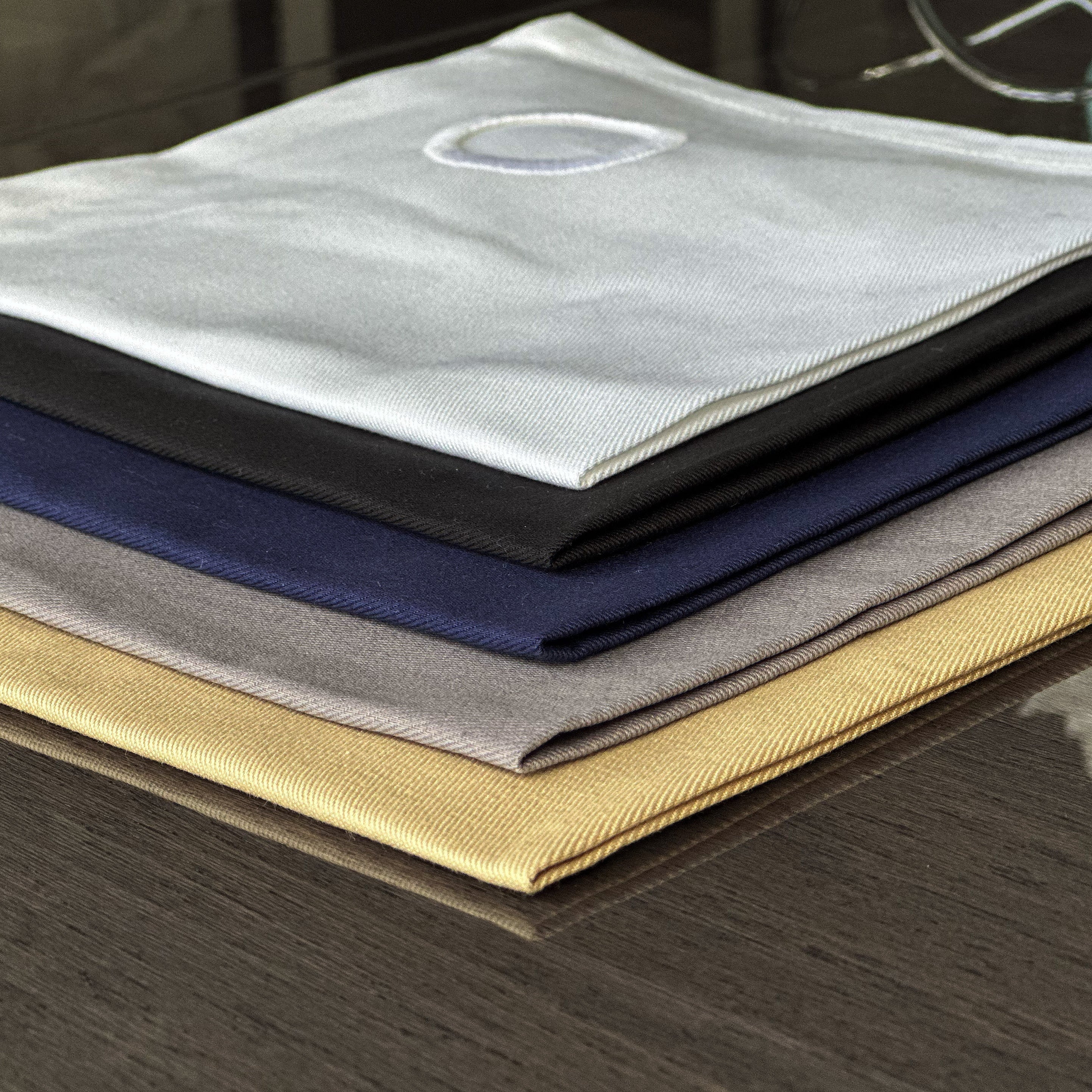

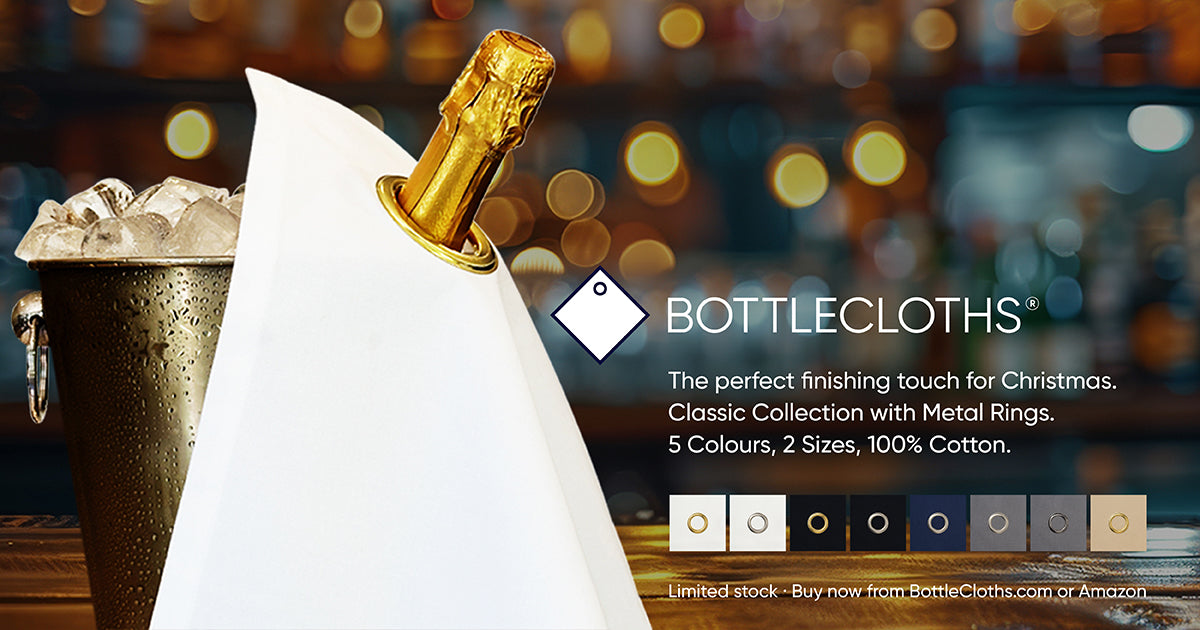

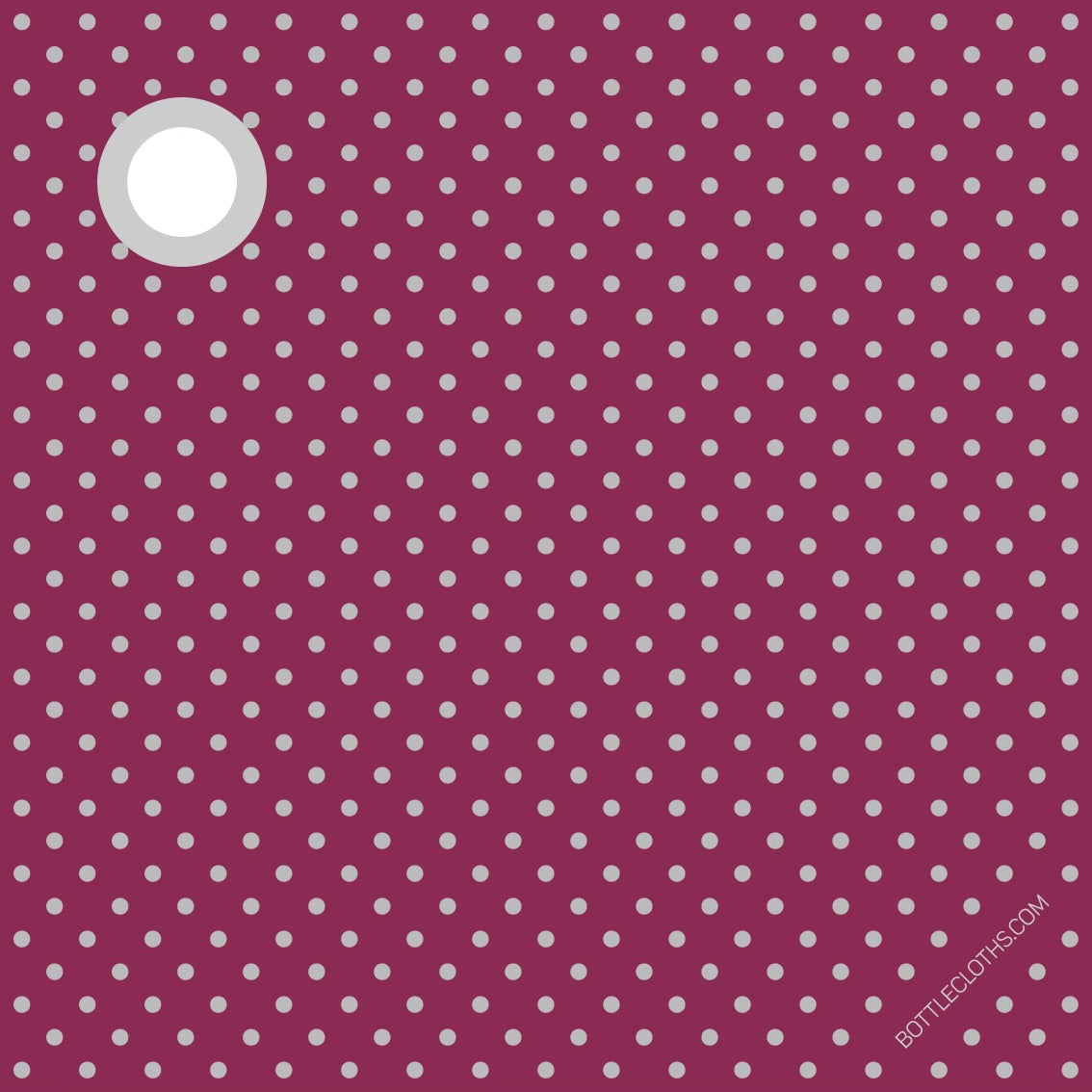

في يناير ٢٠٢٤، وبمساعدة من العائلة والأصدقاء، أطلقنا رسميًا BottleCloths بمجموعاتنا الثلاث الأولى؛

اليوم، تُباع منتجاتنا عالميًا، ويمكن رؤيتها في بعض أشهر المؤسسات حول العالم. وبحلول عام ٢٠٢٥، افتتحنا أول مستودع دولي لنا مع شحن في نفس اليوم إلى الولايات المتحدة من سبيس كوست، فلوريدا، وبعنا منتجاتنا في أكثر من ٣٠ دولة.

ابتكرنا غطاء الزجاجة لتقديم النبيذ أو الشمبانيا أو الماء بأناقة، دون أي تنقيط، من دلاء الثلج ومبردات النبيذ.

ببساطة، مهمتنا هي إيقاف التساقط!

مع السلامة!

كيلي

x

الرحلة